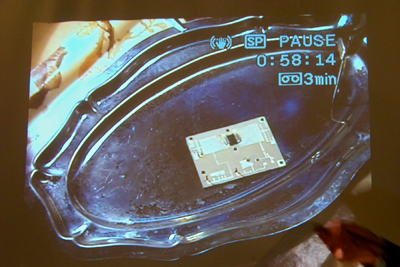

“Surface Mount Construction Techniques” was the subject of the Presidential Address of new LRS President Pete Bates GM4BYF on Wednesday 14th September 2011 at the Braid Hills Hotel. This was very much a practical talk on the difficulties of soldering those pesky little SMC components onto circuit boards. Pete’s Powerpoint slides (see below) contained numerous hints on handling the little devils and the use of a CCTV camera with a close-up lens allowed the audience to follow the microscopic procedures which he demonstrated.

At the end of this report are photographs supplied to Pete by Chris GM4YLN of an improved hold-down device for SMCs.

A family-sized meat-pie tray makes a convenient working surface when earthed.

Alternatively a stainless-steel serving tray can be “borrowed” from the XYL (shhh).

A selection of tweezers is essential for picking up the tiny SMC components

Pete recommended the use of a temperature-controlled soldering iron with a very fine-tipped bit.

Keep all components in marked bags until required, only handle one component at a time, and have plenty of spares in case of loss during construction. (Once a component flies off, you will NEVER find it)!

The use of a hold-down tool is essential when soldering a component onto the board.

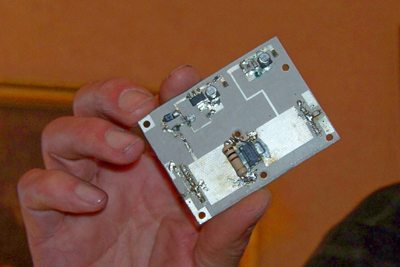

In the exciting conclusion to the presentation Pete demonstrated the soldering of a resistor onto a board.

Success!

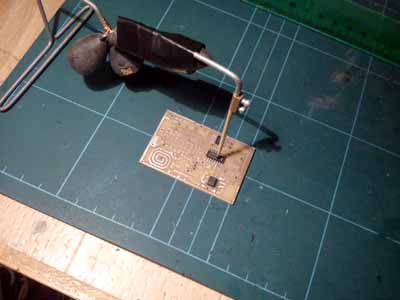

After attending Pete’s lecture, Chris GM4YLN provided the following photos of an improved hold-down device for SMCs that he has developed. It is made from a coat hanger and some fishing weights and a part from a chocolate block connector to hold the cocktail stick. Chris claims it is very easy to use.

Improved SMC hold-down device developed by Chris GM4YLN. (Patent pending)!

Surface mount Construction

1. You can do it !

2. The Difficulties:

2.1 The Components

Small

Athletic

Identification

Handling

2.2 Soldering

Seeing your work

Holding components in place – no tombstones please

Making a good connection

Easy to get too much solder

Static

Overheating

3. The Solutions:

3.1 Solutions -1

Buy a family size meat pie

Cook it

Eat it

Utilise the Aluminium tray

Attach it to the mains earth

3.2 Solutions -2

Obtain Tweezers

Make a hold down tool

Use a fine tip temperature controlled iron

Get some no residue flux

Use very fine solder

3.3 Solutions -3

Keep all components in a marked packet until needed

Only deal with one component at a time

Get some reels of desoldering braid

Solder smallest components first

Inspect each joint as you make it

Get spare resistors & capacitors